Additive Manufacturing of BMGs

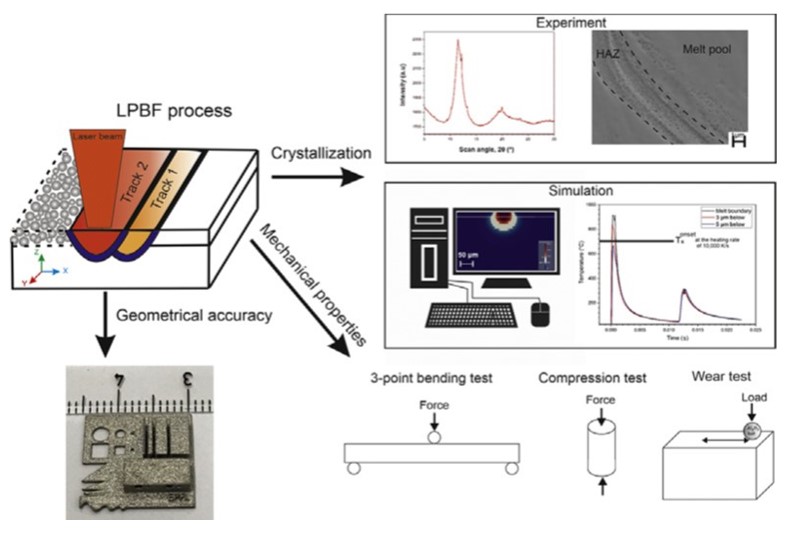

This project deals with the process of laser-powder bed fusion (LPBF) to produce additively manufactured BMG parts. We show that dense and crack-free LPBF-processed BMG parts can be produced with high hardness, high compressive and flexural strength, and excellent geometrical accuracy. We also apply in situ structural and thermal characterization techniques, such as synchrotron XRD and fast calorimetry, to compare the characteristic LPBF processing times with the potential crystallization times of the LPBF-processed BMG powder.

The project is part of a strategic focus area on advanced manufacturing supported by the Swiss ETH domain.